PRODUCT

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

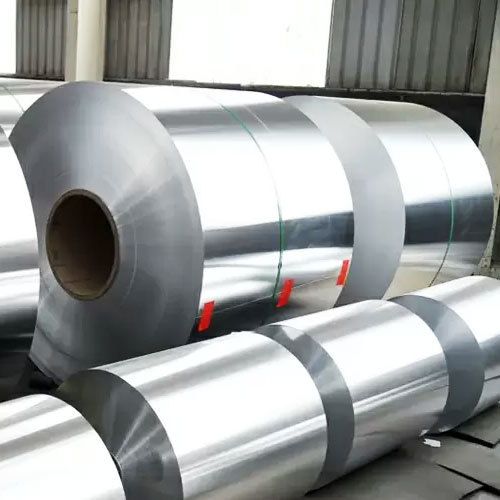

Aluminum alloy 1050 1060 1100 1235 3003 8011 8079 wholesale aluminium foil 0.1 mm 100 micron thickness

Football Chocolate Aluminum Foil Wrapper 1060 1070 1100 3003 8011 8021 Foil Roll Aluminum Foil For Chocolate Wrapping

3003 Aluminum Coil 0.3mm 0.2mm Aluminum Foil Coil 150 Micron 3003 5052 Aluminum Alloy Coil

Factory price aluminum foil raw material 1230 2036 2124 aluminum foil giant roll

7075 aluminum alloy is a cold - treated forging alloy, high strength, far better than mild steel.

7075 is one of the strongest alloys commercially available.

Under heat treatment, can achieve very high strength characteristics.

7075 is one of the strongest alloys commercially available.

Under heat treatment, can achieve very high strength characteristics.

6063 aluminum alloy material.

The main alloy elements are magnesium and silicon, with excellent machining performance, excellent weldability, extrusion and electroplating, good corrosion resistance, toughness, easy to polish, color film, excellent anodic oxidation effect, is a typical extrusion alloy.

The main alloy elements are magnesium and silicon, with excellent machining performance, excellent weldability, extrusion and electroplating, good corrosion resistance, toughness, easy to polish, color film, excellent anodic oxidation effect, is a typical extrusion alloy.

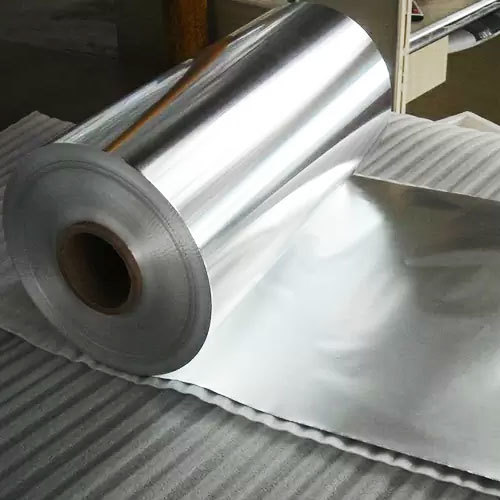

Aluminum foil surface is clean, sanitary, no bacteria or micro-organisms can not grow on its surface.

aluminum foil is a non-toxic packaging material, it can directly contact with food without any harm to human health.

aluminum foil is a kind of tasteless odorless packaging material, will not make the packaging of food have any peculiar smell.

aluminum foil itself is not volatile, it itself and packaged food will never dry or shrink.

at high temperature or low temperature, aluminum foil will not have the phenomenon of oil permeability.

aluminum foil is a non-toxic packaging material, it can directly contact with food without any harm to human health.

aluminum foil is a kind of tasteless odorless packaging material, will not make the packaging of food have any peculiar smell.

aluminum foil itself is not volatile, it itself and packaged food will never dry or shrink.

at high temperature or low temperature, aluminum foil will not have the phenomenon of oil permeability.

Aluminum foil surface is clean, sanitary, no bacteria or micro-organisms can not grow on its surface.

aluminum foil is a non-toxic packaging material, it can directly contact with food without any harm to human health.

aluminum foil is a kind of tasteless odorless packaging material, will not make the packaging of food have any peculiar smell.

aluminum foil itself is not volatile, it itself and packaged food will never dry or shrink.

aluminum foil is a non-toxic packaging material, it can directly contact with food without any harm to human health.

aluminum foil is a kind of tasteless odorless packaging material, will not make the packaging of food have any peculiar smell.

aluminum foil itself is not volatile, it itself and packaged food will never dry or shrink.

2036 aluminum this is an early application of a kind of hard aluminum, commonly known as standard hard aluminum, with moderate strength, annealing, quenching and hot state plasticity is good, heat treatment can be strengthened, quenching and natural aging state in use, spot welding weldability is good.

2036 aluminum alloy features: high strength, a certain heat resistance, can be used for working parts below 150℃.

The strength of 2036 alloy is higher than that of 7075 alloy.

2036 aluminum alloy features: high strength, a certain heat resistance, can be used for working parts below 150℃.

The strength of 2036 alloy is higher than that of 7075 alloy.

1070 aluminum has high plasticity, corrosion resistance, electrical conductivity and good thermal conductivity, but low strength, not through heat treatment to strengthen, cutting is not good, can accept contact welding, gas welding.

Make use of its advantages to manufacture some structural parts with specific performance, such as aluminum foil gaskets and capacitors, electronic tube isolation net, wire, cable protection sleeve, net, wire core and aircraft ventilation system parts and decorative parts.

Make use of its advantages to manufacture some structural parts with specific performance, such as aluminum foil gaskets and capacitors, electronic tube isolation net, wire, cable protection sleeve, net, wire core and aircraft ventilation system parts and decorative parts.

5052 aluminum is Al-Mg alloy aluminum, magnesium is the main alloy element in

5052 alloy aluminum is the most widely used one kind of rustproof aluminum, this alloy has high strength, especially the fatigue strength: High plasticity and corrosion resistance, heat treatment can not be strengthened, in the semi-cold hardening plasticity is good, cold hardening plasticity is low, good corrosion resistance, good weldability, poor cutting performance, polishing.

5052 alloy aluminum is the most widely used one kind of rustproof aluminum, this alloy has high strength, especially the fatigue strength: High plasticity and corrosion resistance, heat treatment can not be strengthened, in the semi-cold hardening plasticity is good, cold hardening plasticity is low, good corrosion resistance, good weldability, poor cutting performance, polishing.

The main alloying elements in 6061 alloy are magnesium and silicon, which have moderate strength, good corrosion resistance, weldability and good oxidation effect.

Widely used in various industrial structural parts requiring a certain strength and high antibiotic corrosion, its main chemical composition: Cu:0.15-0.4; Si: 0.4-0.8; Fe: 0.7 -; Mn: 0.15; Mg: 0.8-1.2; Zinc: 0.25; Cr: 0.04-0.35; Ti: 0.15 -; 6061 aluminum plate its state T6 and T651 difference is that in general, T6 internal stress will be relatively large, processing will be deformed, the most suitable for processing state should be T651, he is on the basis of T6 tensile, eliminate internal stress.

Widely used in various industrial structural parts requiring a certain strength and high antibiotic corrosion, its main chemical composition: Cu:0.15-0.4; Si: 0.4-0.8; Fe: 0.7 -; Mn: 0.15; Mg: 0.8-1.2; Zinc: 0.25; Cr: 0.04-0.35; Ti: 0.15 -; 6061 aluminum plate its state T6 and T651 difference is that in general, T6 internal stress will be relatively large, processing will be deformed, the most suitable for processing state should be T651, he is on the basis of T6 tensile, eliminate internal stress.